掃碼看工(gōng)廠全景

掃碼看工(gōng)廠全景

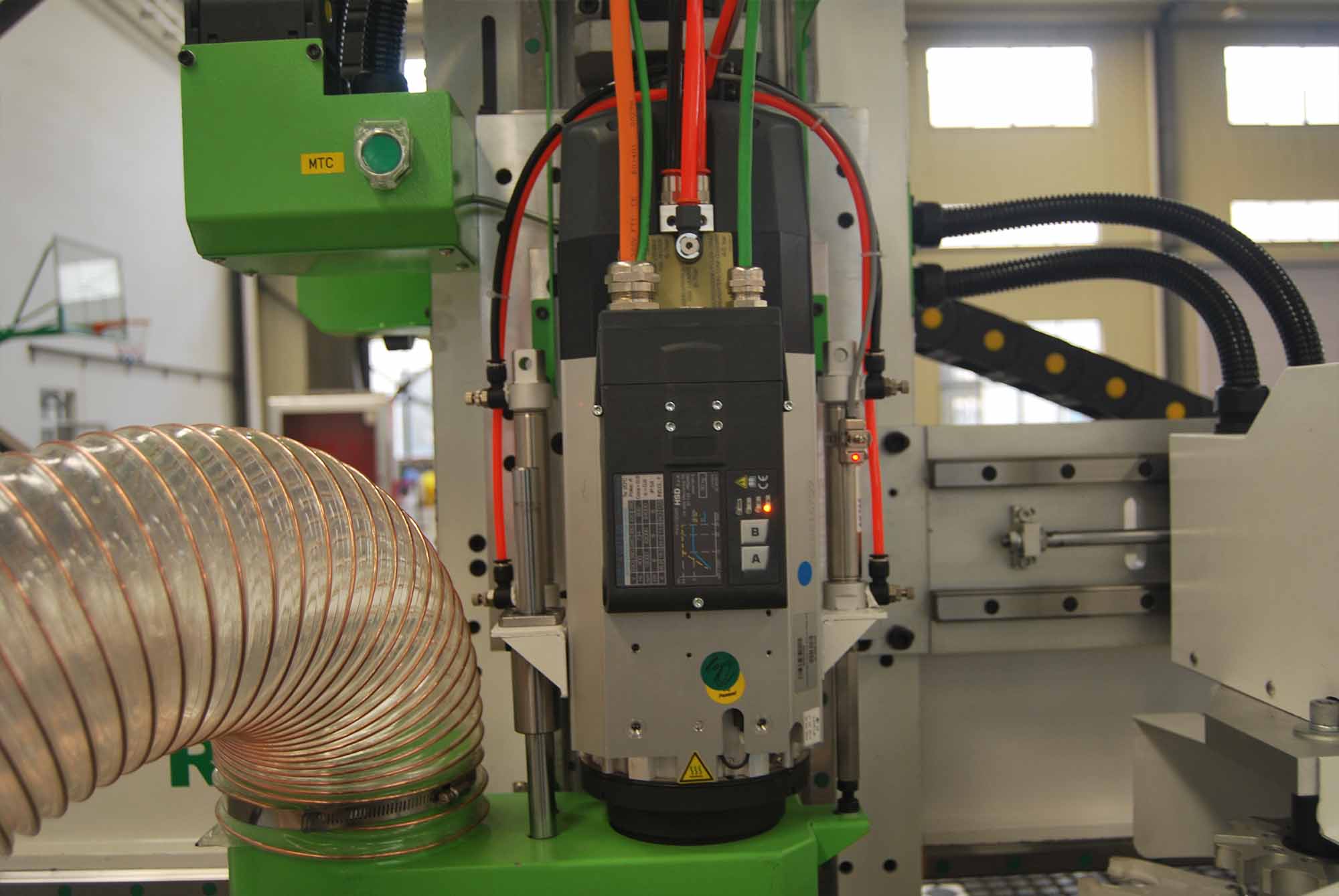

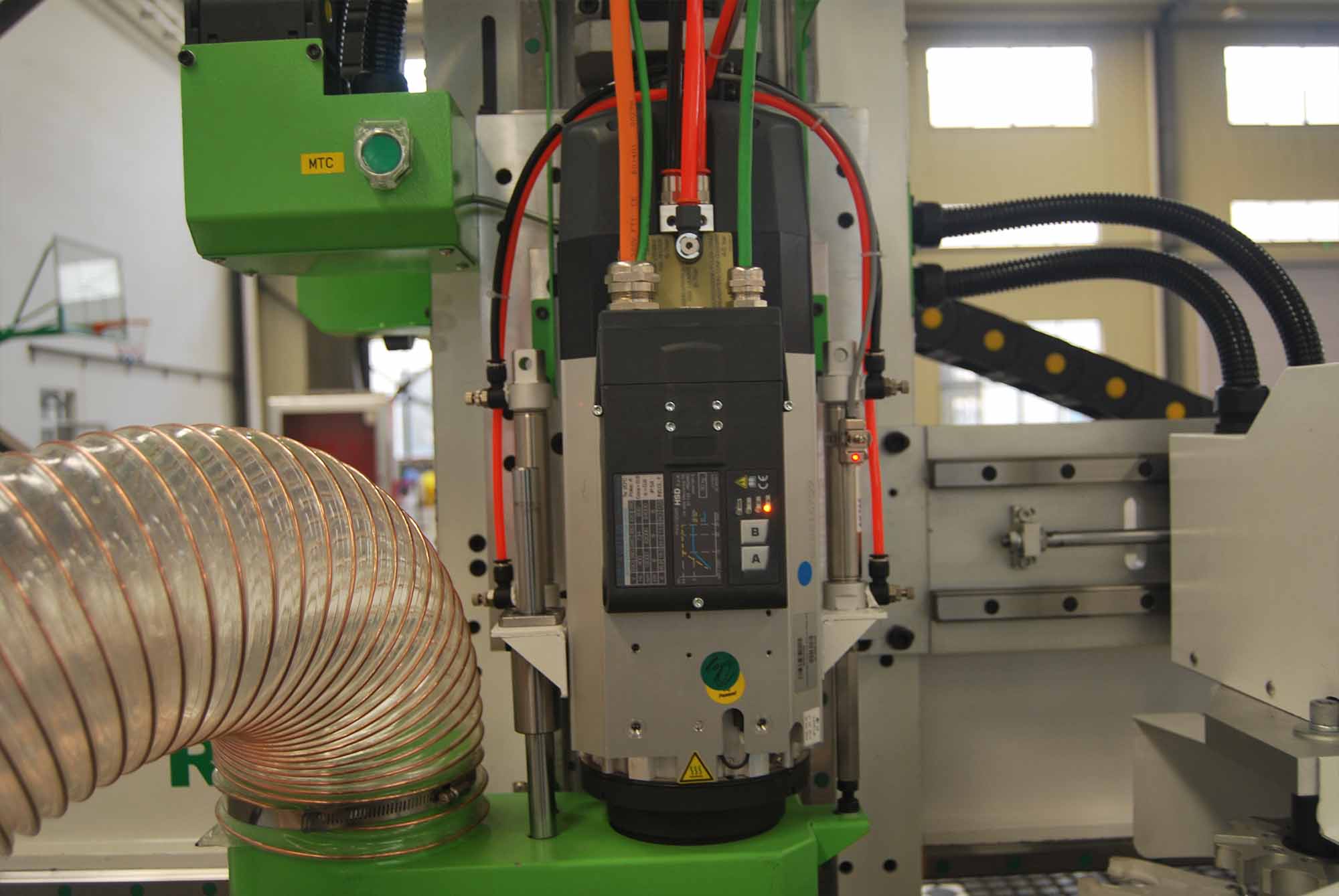

配有Syntec控制器、台灣Hiwin直線導軌、安川伺服電(diàn)機和驅動器、意大(dà)利ATC主軸。

采用自動定位杆,可自動定位物(wù)料,節省大(dà)量時間,提高工(gōng)作效率。

智能加工(gōng)越界保護功能可以防止機械碰撞所造成的過度加工(gōng)。

考慮到客戶對尺寸的不同要求,我(wǒ)們可以提供:RC1325-ATC、RC2030-ATC、RC2040-ATC、RC2550-ATC等。

| X、 Y、Z工(gōng)作區 | 1500x3000x250mm |

| 台面尺寸 | 1560×3440mm |

| X、 Y、Z移動定位精度 | ±0.03/300mm |

| X、 Y、Z重新定位精度 | ±0.03mm |

| 工(gōng)作台表面 | Vacuum and T-slot Combined |

| 框架 | Welded structure |

| X, Y Structure | Rack and Pinion Drive |

| Z Structure | Hiwin Linear Rails and Ball Screw |

| Max. Power Consumption | (Without Spindle) 4.5kw |

| Max. Rapid Travel Rate | 45000mm/min |

| Max. Working Speed | 30000mm/min |

| Spindle Power | 9.6kw |

| Spindle Speed | 0-24000RPM |

| Drive Motors | Yaskawa servo |

| Working Voltage | AC 380V/50/60Hz,3PH |

| Command Language | G Code |

| Operating System | Syntec Control System |

| Computer Interface | USB |

| Flash Memory | 128M(U Disk) |

| Collet | ER32 |

| X,Y Resolution | <0.03mm |

| Software Compatibility | Type3/ Artcam software |

| Running Environment Temperature | 0 - 45 Centigrade |

| Relative Humidity | 30% - 75% |

| Packing Size | 3700X2250X2250mm |

| N.W. | 2600KG |

| G.W. | 2650KG |

| Optional Parts | Dust Collector,Vacuum Pump,Rotary System |

——— 結束

高效、經濟、預算友好的數控雕刻機

上一(yī)頁:圓盤換刀加工(gōng)中(zhōng)心 RC1530S-ATC

下(xià)一(yī)頁:數控機床 1325S-ATC